Breaking rock below ground? It’s tough work. Having the right equipment to crush rock is absolutely essential. Underground rock breakers completely change the game in mining and tunneling. They power through the hardest surfaces. This keeps operations running without a hitch. But finding the ideal one? That is the real challenge. This guide covers all the important details for you. We will talk about rock kinds, machine specifications, and much more. It will help you select an underground rock breaker that is perfect for your job. Let’s get started.

What Exactly Is an Underground Rock Breaker?

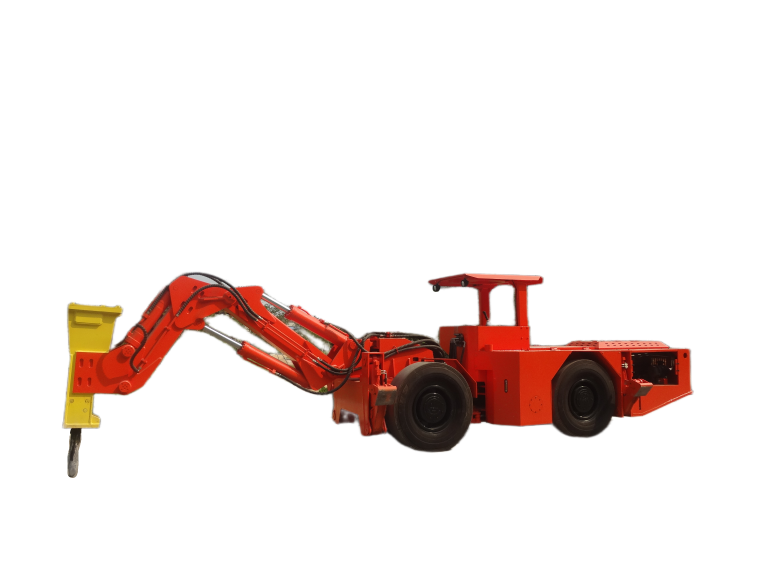

Let’s begin with the basics. An underground rock breaker is a very strong tool. It is built to break apart rocks in small, tight spaces. Think of mines or tunnels. Imagine powerful hydraulic hammers fixed onto excavators or small rigs. They provide accurate, forceful hits. These tools are vital for many tasks. They clear huge rocks, fix crusher blockages, and prepare areas for blasting.

Important Parts

Hammer/Chisel: This is the part that does the work. It is made from top-quality steel, like 40CrMo or 42CrMoA. It smashes the rock.

Hydraulic System: This gives power to the piston. It transfers force using high-pressure fluid.

Mounting Arm: This links the breaker to carriers, such as excavators or loaders. It makes sure everything stays steady.

Control System: It can be manual or remote. Newer versions, such as the underground rock breaker from Yantai Chi Hong, provide remote control. This is much safer.

Shock Absorbers: These lower the vibration. They keep operators and machinery safe.

All these components function as a team. They break rock effectively and securely.

The Importance of Selecting the Correct Underground Rock Breaker

Make a poor choice? You will face holdups, machine failures, and rising expenses. The correct breaker increases output, lowers stoppages, and ensures worker safety. In below-ground conditions, space is limited and dangers are everywhere. Here, accuracy and dependability are super important.

Advantages Compared to Older Techniques

No Dangers from Blasting: Breakers don’t produce flyrock or shaking like explosives do. This makes things safer for the team.

Accuracy: You can hit specific rocks and not harm surrounding structures.

Better for the Environment: They make less sound and no blast pollution. This is great for sensitive areas.

Works Quickly: They break rock much faster than people can. This means projects finish sooner.

Take one real case. Underground Rock Breaker was used in an underground mine. It lowered crusher blockages by forty percent. It also improved material flow by a quarter.

Key Points to Think About When Selecting an Underground Rock Breaker

Selecting the right breaker should not be a random guess. Focus on these areas.

Know Your Rock Type

Rocks are not all the same. Their hardness, density, and how they break will guide your choice of breaker.

Soft Rocks (like Sandstone or Limestone): These require less force. Breakers that are lighter can manage.

Hard Rocks (like Granite or Basalt): These need a lot of impact energy. Pick heavy-duty options. You should test the rock hardness. Use the Mohs scale. Or get advice from geologists to be sure.

Look at Rock Size and Amount

Dealing with big boulders? Or smaller pieces? The size is very important.

Large Boulders: You need breakers that deliver high impact energy. They should hit between 500 and 1500 times per minute.

Small Rocks: Lighter breakers that hit more often are fine. They can reach up to 2000 blows each minute.

You must also guess the total volume. Jobs with a lot of rock need strong, long-lasting tools. This stops them from getting too hot.

Check the Surrounding Conditions

Underground places are special. They have limited room, bad air flow, and strict safety laws. These factors influence your decision.

Tight Spaces: Choose smaller breakers.

Noise and Vibration Rules: Electric breakers or box-type hydraulic ones make less noise.

Air Flow: Electric breakers don’t release fumes. This is best for mines with poor air movement.

Always look up local rules. Some places do not allow very loud machinery.

Pair the Breaker with Your Carrier Machine

Your breaker has to work well with your excavator or loader.

Weight Match: The breaker’s weight must not be more than the carrier can take. For instance, a 1-ton excavator works with a light breaker. That means 100 to 200kg.

Hydraulic Flow and Pressure: The breaker’s flow rate needs to match the carrier’s output. It is usually between 20 and 150 L/min. If they don’t match, it can cause overheating or poor results.

Mounting Style: Make sure the arm fits. It could be top, side, or box-type. Box-type breakers, like those from Yantai Chi Hong, keep out dust.

Here is a simple table for breaker-carrier matching:

| Carrier Size | Breaker Weight | Flow Rate (L/min) | Applications |

| 1-5 tons | 100-400kg | 20-50 | Small tunnels, soft rock |

| 10-20 tons | 400-1000kg | 50-100 | Medium mines, hard rock |

| 20-50 tons | 1000-2000kg | 100-150 | Large-scale mining |

Select the Proper Chisel Type

Chisels are what touch the rock. You must choose carefully.

Conical: It focuses the force for deep penetration. Best for hard rock and concrete.

Pyramidal: It makes exact slots or grooves. Good for tunneling jobs.

Blunt: It spreads the impact over a wider area. Ideal for big, dense materials.

Wedge: It helps with controlled breaking. Works well for soft or mixed rock.

Match the chisel to your rock type and what you need to do. This gives you the best results.

Think About the Power Source

Breakers can use hydraulic, pneumatic, or electric power.

Hydraulic: This is the most usual. It gives high power for difficult jobs. But it needs a strong carrier machine.

Pneumatic: These are flexible and easy to move. Good for smaller tasks or changing conditions.

Electric: They are quiet and have no emissions. Perfect for closed mines or city sites.

Hydraulic is the leader underground. This is because of the high power demands.

Put Maintenance and Long Life First

When machines stop working, you lose money. Pick breakers that are built to keep going.

Material Quality: Steel of high grade, for example 42CrMoA, fights off wear.

Ease of Maintenance: Find models with parts that are easy to reach. Look for automatic lubrication systems. The breakers from Yantai Chi Hong have closed housings. These keep out dirt.

Warranty and Support: Aim for warranties of one year. Yantai Chi Hong gives one for 2000 engine hours. Help after the sale is also crucial.

Remember to add grease every one to two hours. This stops the bushings from wearing out.

Safety Elements

Working underground has risks. Always think of safety first.

Remote Control: This lets operators stay away from dangerous spots.

Vibration Reduction: It lowers operator tiredness. Breakers with Epiroc parts are great at this.

Emergency Stop Buttons: These are very important. They allow fast shutdowns if something goes wrong.

Where Underground Rock Breakers Are Used

These tools are helpful in many below-ground situations.

In Mining Work

Getting Ore Out: Break very large rocks so they can go into crushers.

Making Things Smaller: Reduce big boulders that are too large for loaders.

Mining in Thin Veins: Small breakers fit in very tight tunnels.

In Tunneling and Building Underground

Digging Tunnels: Remove hard rock to create pathways.

Grouting and Bolting: Prepare holes to make things stable.

Infrastructure Projects: Help with building country roads and water systems in China.

In Demolition and Recycling

Break up concrete or waste in below-ground buildings.

Get materials ready to use again. This cuts down on waste.

Tips for Maintenance to Make It Last Longer

Keep your breaker in good shape with these steps.

Check Daily: Look at hoses, chisels, and seals for damage. Watch for oil leaks.

Greasing: Put grease on the bushings every one to two hours. This prevents them from sticking.

Nitrogen Pressure: In breakers that use gas, check the reservoirs. Change for hot or cold weather.

Storage: Use a cover. This shields wires from dust and wetness.

Yantai Chi Hong provides four check-ups for free in the first year. They give full reports.

Learn About Yantai Chi Hong: A Supplier You Can Rely on for Underground Rock Breakers

Need a breaker that won’t fail? Yantai Chi Hong Machinery Co., Ltd. can help. They are in Yantai, China. With twelve years of experience, they have a big production area of 96,000 square meters. Over three hundred people work there, including sixty technical experts. Their underground rock breakers use Deutz engines and Epiroc hammers. They manage hard rock in cramped areas. They have EU CE and ISO9001:2015 certificates. They offer help around the world after you buy. The warranty is for one year or two thousand engine hours. You also get four free check-ups. Visit ytchihong.com to learn more.

Wrapping Up

Picking the right underground rock breaker is about fit. Match the tool to your rock kind, job size, and surroundings. Think about carrier fit, chisel type, power source, and safety parts. A smart choice makes work faster, reduces stops, and protects your team. Spend wisely, take good care of it, and your breaker will perform well for a long time.

Frequently Asked Questions

How do I choose an underground rock breaker for small tunnels?

Go for a small model. Yantai Chi Hong is a fine pick. You will understand this when you are choosing an underground rock breaker.

What chisel is best when choosing an underground rock breaker?

For hard rock, use conical chisels. Use blunt ones for thick materials. When you are choosing an underground rock breaker, you must match the chisel to your rock type.

Are hydraulic breakers good when choosing an underground rock breaker?

Yes, they are. Hydraulic breakers provide great power for tough rocks. They are a solid choice when you are choosing an underground rock breaker for mining or tunneling work.

How often should I maintain my underground rock breaker?

Add grease every one to two hours. Check hoses each day. If you are choosing an underground rock breaker that is easy to care for, like those from Yantai Chi Hong, you will save effort.

Can I use an underground rock breaker for concrete?

Yes, you can. When you are choosing an underground rock breaker, pick one with a conical or pyramidal chisel. That is what you need for breaking up concrete.