Rock drill tools are the core component of efficient drilling operations. Yet, extreme wear and damage can quietly compromise their functionality. Spotting the early warning signals of degradation is vital. This maintains productivity, safety, and cost-effectiveness. Here are the top five indicators that your equipment requires replacement—before they cause more significant issues.

What Are the Warning Signals of Extreme Wear on Rock Drill Tools?

Extreme wear on rock drill bits doesn’t occur suddenly. It develops progressively, often showing faint signals like edge rounding and surface flaking. Ignoring these initial symptoms can cause reduced drilling effectiveness, greater energy use, and even equipment harm. Consistent checks are crucial for catching damage before it worsens.

Detecting Edge Rounding and Surface Flaking

Extreme wear on rock drill bits often starts subtly. Edge rounding and surface flaking are common signs. These symptoms show the bit’s cutting power is weakened. Edge rounding lessens the bit’s capacity to penetrate tough rock efficiently. Surface flaking can cause further material breakdown. These problems might not be instantly clear. However, they can be found through regular visual checks and microscopic examination.

Measuring Loss of Hardness in Cutting Faces

As drill bits deteriorate, their cutting faces soften. This happens from long exposure to intense heat and rubbing during drilling. This softening reduces the bit’s capacity to stay sharp under force. Rock drill tools are made of substances like carbide or high-carbon steel. These offer high wear resistance and toughness. When this quality weakens, it signals the necessity for prompt replacement.

Noting Increased Chipping Frequency

Regular chipping or spalling along the bit’s edges is another warning sign. This can stem from incorrect alignment, too much feed pressure, or drilling into very abrasive rock. In rocks with higher hardness, rock drill tools deteriorate quicker. Consequently, the frequency of replacement rises.

Yantai Chi Hong Machinery highlights consistent examination and cleaning of rock drill tools. This maintains optimal working states and extends service duration.

How Does Reduced Drilling Effectiveness Signal Equipment Failure?

A fall in drilling results is one of the most obvious indicators that your rock drill tools are wearing down. Longer drilling periods, heightened energy use, and dropping penetration speeds all point to equipment past its best. Fixing these problems swiftly guarantees your activities stay on course.

Longer Drilling Period Per Meter of Rock

When a drill bit needs more time to penetrate each meter of rock, it’s a definite sign its results have worsened. This inefficiency could come from dulled cutting edges or worn surfaces. These no longer keep ideal contact with the rock face.

Greater Energy Use During Operation

Damaged equipment demands more energy to achieve the same result. If your machinery is using notably more power without increased output, it’s likely compensating for inefficient tools. Construction strength is also an important element impacting the service duration of rock drill tools.

Declining Penetration Speeds

A visible drop in penetration speed—how fast the bit moves through rock—indicates weakened equipment effectiveness. This directly impacts productivity and raises operational expenses over time.

Yantai Chi Hong Machinery proposes evaluating work effectiveness regularly. When irregular states like breakage or deformation happen, swift replacement guarantees safety and expense control.

What Kinds of Abnormal Vibrations or Sounds Indicate Equipment Problems?

Unusual vibrations or grinding noises during drilling aren’t just irritations. They signal misalignment, bit harm, or resonance impacts that can weaken accuracy and safety. Listening to your machinery can prevent expensive malfunctions and ensure exact drilling outcomes.

Vibration Patterns Connected to Misaligned Bits

Misalignment between the drill tool and machine causes uneven vibration patterns. These vibrations not only lessen precision but also speed up damage on both the bit and machine parts.

Audible Clues from Uneven Bit‐rock Contact

Grinding sounds, squealing, or abrupt changes in noise levels often indicate irregular contact between the bit and rock surface. This shows the bit is either harmed or wrongly seated.

Resonance Impacts on Drilling Accuracy

Resonance caused by worn or cracked bits can distort drilling paths. This compromises precision in applications like tunneling or geological exploration. Exact hole placement is critical here.

Yantai Chi Hong Machinery recommends replacing any tool showing noticeable vibration or noise during use. This is part of proactive upkeep.

When Do Cracked or Misshapen Parts Demand Replacement?

Cracks, distortions, or bending in drill tool parts aren’t just surface issues. They present major safety dangers. Operating with weakened tools can cause equipment malfunction or even incidents. Instant replacement is the only safe answer.

Finding Visible Cracks on Tool Bodies

Cracks are significant structural flaws that weaken safety. When a rock drill tool undergoes abnormal states like breakage, cracks, or bending, it should be swapped for a new one quickly. This ensures building safety and effectiveness.

Finding Shank Bending and Coupling Harm

The shank joins the drill bit to machinery. Any bending here impacts alignment and results. Likewise, worn couplings can cause slipping or poor torque transfer.

Evaluating Safety Dangers from Part Malfunction

Operating with weakened parts increases the chance of incidents or equipment breakdowns. Both are costly results that can be prevented through timely replacements.

Yantai Chi Hong Machinery offers expert after-sales help. They encourage using OEM parts for safe operation during replacements.

Why is Result Consistency Vital for Drilling Projects?

Irregular drilling results leads to uneven holes, project hold-ups, and unforeseen costs. Keeping high-standard tools ensures precision, efficiency, and long-term savings. These are key elements in successful drilling activities.

Impact of Equipment Weakening on Hole Precision

Precision in hole size and depth is essential for blasting effectiveness in mining or anchoring in building. Damaged tools produce uneven holes that affect later steps.

Influence on Total Project Schedules

Delays from frequent tool swaps or re-drilling due to poor hole quality directly impact project timelines. Timely fixing or replacement of the drill tools can boost the effectiveness of rock drilling and lower expenses.

Expense Consequences of Unforeseen Tool Changes

Unplanned replacements not only add material costs but also increase worker downtime. This is especially true if spare parts aren’t easily available onsite.

Yantai Chi Hong Machinery assists clients with spare parts consignment services. These cut downtime by guaranteeing rapid access to essential components.

Who is Yantai Chi Hong Machinery Co., Ltd.?

With over 12 years of skill in mining equipment, Yantai Chi Hong Machinery Co., Ltd. specializes in high-performance rock drill tools built for longevity. Their dedication to quality substances, modern production, and 24/7 worldwide assistance makes them a dependable choice for demanding drilling applications.

Provider of High‐caliber Rock Drill Tools

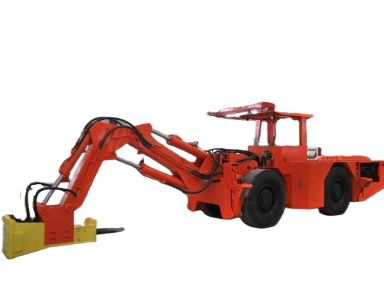

Yantai Chi Hong Machinery Co., Ltd. has developed steadily in the underground mining field for 12 years. They offer a full range of mining machines including loaders, dump trucks, jumbos—and importantly—rock drilling tools designed for tough conditions.

Focus on Substance Choice and Production Benchmarks

Rock drill tools are made of substances like carbide or high-carbon steel. These are picked specifically for their endurance under harsh conditions. Yantai Chi Hong uses sophisticated production methods. These include cold installation techniques using liquid nitrogen to extend equipment life.

Committed Worldwide Assistance and After-sales Service

Their 24/7 client support network includes fast response teams. These can fix malfunctioning equipment within one day—a key benefit for time-sensitive operations. Our company provides complimentary upkeep (except for human reasons) for quality issues within 12 months after delivery. This ensures peace-of-mind post-purchase.

Conclusion

Never overlook early signals of deterioration on your rock drill tools. Edge rounding, increased chipping, odd vibrations—all point toward falling results that impact safety, cost-efficiency, and project schedules. Steady examination routines paired with specialist assistance from makers like Yantai Chi Hong Machinery Co., Ltd., are key. They provide durable goods supported by responsive service networks. This helps guarantee continuous productivity across mining activities.

FAQs

What Elements Shorten the Service Duration of Rock Drill Tools?

Rock hardness is a critical element affecting the service duration of rock drill tools. Other contributors include incorrect operation methods, high-intensity building environments, unsuitable equipment choice for specific rocks, and absence of regular upkeep.

How Frequently should Tools be Examined for Signals of Deterioration?

Consistent examination and cleaning of the rock drill tools can preserve its proper working state and prolong its service duration. Based on operating intensity and setting complexity, weekly inspections might be suitable.

Can Equipment Refurbishment Extend Service Duration?

Yes—sharpening edges or re-hardening surfaces might restore partial function—but only if structural soundness remains intact. Otherwise, when deterioration passes a specific point (for instance, if diameter wear exceeds 10% of the original diameter), it is essential to think about replacing rather than refurbishing.