+

Underground mining pushes teams to their limits. Narrow tunnels. Hard rock that fights back. Every minute counts when you’re racing against time and tough conditions. That’s where underground rock breakers step in. These machines break through obstacles fast and smart, turning slow grinds into smooth operations. They don’t just smash rock—they clear the way for quicker digs, safer shifts, and bigger hauls. If you’re a mine supervisor eyeing better output or an operator tired of stalled jobs, stick around. We’ll dig into rock breaker underground mining work.

The Tough Side of Underground Mining

Mining below ground isn’t like surface work. Space squeezes you. Rock laughs at drills sometimes. And safety? It’s non-stop. Teams face these hurdles daily, and they eat into profits if you let them.

Cramped Spaces and Tight Turns

Picture this: You’re in a tunnel barely wide enough for your gear. Wheeling around feels like threading a needle. Old methods—hammers, chisels, basic jacks—bog down here. They need room to swing, and when there’s none, work stops. Underground rock breakers change that. Their compact builds slip into spots others can’t reach. Booms fold and twist just right, letting you hit the rock without backing out. Short shifts turn longer. Crews move forward instead of circling back.

One miner I talked to said it plain: “We used to lose half a day repositioning. Now? We break and go.” That kind of flow keeps schedules on track.

Battling Hard Rock Head-On

Rock down there varies. Some crumbles easy. Others? Solid walls that chew up bits and blades. Fragmenting it wrong leads to big chunks that jam loaders or slow haul trucks. Enter hydraulic-powered breakers. They deliver steady thumps—hundreds per minute—that crack rock clean. No wild swings. Just controlled force that sizes pieces for easy haul-off.

Think about the math. A single breaker can handle what took a team hours before. Energy stays low, noise drops too. Your crew focuses on the job, not the racket.

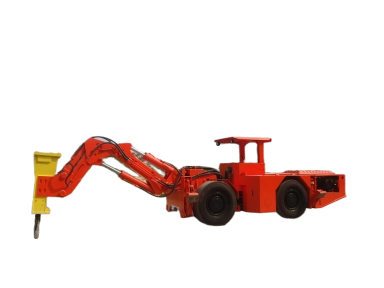

Inside an Underground Rock Breaker

What sets these machines apart? It’s the smart design packed in. Built for the dark, they handle dust, damp, and daily knocks without flinching.

Power from Hydraulics

At the heart sits the hydraulic system. Oil under pressure drives the hammer, turning engine grunt into pinpoint breaks. It adjusts on the fly—soft taps for loose stuff, hard hits for granite. That flexibility means less waste. Rock breaks even, ready for the next step.

Operators love the feel. Smooth controls let you work from the cab, eyes on the face. No guesswork. And with impacts up to 1,200 blows a minute, jobs wrap quicker than you think.

Booms That Bend to Your Needs

The boom’s no afterthought. It’s the reach arm, built to stretch into corners. Articulated joints let it pivot 360 degrees, cover heights from floor to ceiling. In a 3-meter tunnel, that’s gold. You position once, break wide.

Add remote options, and it’s even better. Step back from flyrock risks. Watch from safety while the machine does the heavy lift.

| Feature | Traditional Breaker | Modern Underground Rock Breaker |

|---|---|---|

| Reach | Fixed, limited angle | Articulated boom, full rotation |

| Power Delivery | Manual or basic hydraulic | Variable pressure, 50-200 kW range |

| Size for Tunnels | Bulky, hard to maneuver | Compact, 1-10 ton weights |

| Impact Rate | Low, inconsistent | 200-1,200 bpm, steady force |

This table shows the gap. New breakers fit tight spots and pack more punch without the bulk.

Driving Efficiency in Every Shift

Efficiency isn’t buzz—it’s dollars. Underground rock breakers deliver by speeding cycles and trimming waste. Mines see real shifts when these tools join the fleet.

Faster Breaks, Quicker Cycles

Breaking rock sets the pace for everything else. Load, haul, dump—it all waits on that first crack. A good breaker cuts time per face by 30-50%. What took eight hours? Now four. Crews advance meters daily, not inches.

In one tunnel project, teams hit targets weeks early. More footage meant more ore. And with even fragments, loaders scoop clean—no sorting hassles.

Less Downtime, More Uptime

Breaks stall when tools fail. Dust clogs. Parts wear. But these breakers run cool and clean. Low-vibration designs spare the boom from cracks. Seals hold against wet blasts.

Maintenance? Simple swaps, no full teardowns. A quick check keeps you rolling. Downtime drops, and that adds up. One site figured 20% more run time yearly.

Boosting Overall Output

It’s chain reaction. Quick breaks feed faster loading. Trucks roll full. The whole line hums. Managers track it in tons per shift—upward ticks that pay bills.

- Resource Savings: Less fuel per meter broken. Hydraulics sip power.

- Labor Wins: Fewer hands on risky manual breaks. Redirect to high-value tasks.

- Scalability: Handle bigger faces or switch to support roles seamless.

These gains stack. A mid-size mine might add 15% to yearly yield. That’s not small potatoes.

Keeping Safety in the Spotlight

Mines thrive when crews come home whole. Rock breakers shine here, cutting hazards that sneak up underground.

Dodging Rockfall Risks

Uncontrolled blasts send shards flying. Big falls bury gear. Breakers tame that. Precise hydraulics mean targeted hits—no loose slabs left hanging. Faces stay stable longer.

Cabs shield operators too. Thick glass, roll bars. You work close but covered. Incidents? Way down. One report showed 40% fewer flyrock claims after switching.

Easing Operator Strain

Long shifts wear you out. Vibration shakes bones. Noise rings ears. Modern breakers quiet the roar—under 100 dB. Cushioned seats, easy joysticks cut fatigue.

Train up quick, and errors drop. Safety logs reflect it: Fewer slips, better focus. Healthy teams stick around, building know-how over time.

Lessons from the Field

Real mines tell the best stories. Across borders, breakers prove their worth in dirt and rock.

Take a Peruvian dig. Narrow veins, hard basalt. Traditional jacks lagged. Breakers? They chewed through, upping advance rates 25%. Safety held firm—no major falls. Output climbed, costs dipped.

In the Philippines, loaders paired with breakers cleared waste fast. Precision parts meant less jam-ups. Productivity jumped 18%, with crews praising the smooth flow.

South Africa brought tough ore. Frames built strong took the beating. Welds held, runs extended. Sites hit quotas early, banking extra shifts for maintenance.

Chile’s test ground mimicked chaos—wet, dusty. Breakers passed with flying colors. ERP tracking showed uptime at 95%. Teams trusted the gear, pushing harder safely.

These spots? Varied geology, same win: Efficiency up, risks down. Your mine could echo them.

Smooth Support Keeps Things Running

Gear’s only as good as its backup. Solid service turns buys into partners.

Daily checks? Guides walk you through. Spares arrive fast—OEM quality, no fakes. Tech lines answer mid-shift snags.

Training fits your crew. Hands-on sims build skills. Preventive plans spot wear early, dodging big fixes.

One operator noted: “Their team flew in for a tune-up. Back online in days.” That reliability? It binds loyalty.

Meet Your Underground Rock Breaker Partner

Yantai Chi Hong Machinery Co., Ltd. stands as a trusted supplier of underground rock breakers. With 12 years deep in mining gear, they’ve built a full chain—from design to delivery. Based in Yantai, China, their 96,000-square-meter shop hums with 300-plus builders, half seasoned pros. Certifications like EU CE and ISO9001:2015 back their work. They craft tools for loaders, trucks, scalers, and breakers that fit global needs. Focus stays sharp: Reliable kit that boosts your digs without the fluff.

Wrapping It Up: A Clear Path Forward

Underground mining demands grit and gear that delivers. Rock breakers bring both—breaking barriers, safeguarding teams, and stacking wins. From cramped tunnels to hard faces, they turn challenges into checkpoints. Pair them with smart support, and your operation levels up. Not tomorrow. Today. Ready to see the difference? It’s time to break ground smarter.

Frequently Asked Questions

What exactly does an underground rock breaker do in mining?

An underground rock breaker uses hydraulic force to crack tough rock in tunnels and shafts. It enhances underground mining by sizing fragments just right for loaders, speeding up the whole process without big blasts.

How does a rock breaker improve safety down the mine?

Rock breakers cut risks by controlling each hit—no wild chunks flying. Operators stay in protected cabs, away from the action. This setup enhances underground work, keeping crews safer and shifts on track.

Can rock breakers handle different tunnel sizes?

Sure, their booms adjust to fit tight spots or wider drifts. Compact designs slip through narrow veins, making them a go-to for varied digs. They boost mining efficiency wherever space plays a role.

What’s the upkeep like for these machines?

Keep it simple: Regular oil checks and part swaps. With good service, they run years without hiccups. That low fuss means more time breaking rock, less fixing—straight gains for your output.

Why pick a hydraulic rock breaker over older methods?

Hydraulics deliver steady power, quiet runs, and quick breaks. They slash downtime and labor needs, directly enhancing underground mining efficiency. Old ways work, but these? They win the long game.