If you’re in the mining world, you know how crucial the right gear is for getting the job done safely and quickly. Underground mining throws all sorts of challenges your way – tight spaces, tough rock, and the need for precision. That’s where top underground drill jumbos come into play. These machines drill holes for blasting or bolting, setting the stage for everything else in the operation. In this post, we’ll dive deep into what makes these drill jumbos stand out, how they work underground, and tips to keep them running strong. Whether you’re a site manager eyeing new equipment or an operator looking to sharpen your skills, this guide has you covered.

What Makes a Drill Jumbo Essential in Underground Mining?

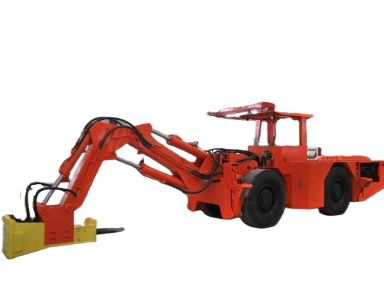

Underground mining isn’t like digging in your backyard. It’s dark, cramped, and demands tools that can handle the pressure. A drill jumbo is basically a mobile rig with arms – or booms – that hold drills. It punches holes into rock faces for explosives or support bolts. Without it, advancing tunnels or extracting ore would slow to a crawl.

Think about it. In a typical underground setup, you need to blast rock to loosen material. The drill jumbo gets in there first, creating precise patterns of holes. This isn’t just about speed; it’s about safety too. Poor drilling can lead to unstable walls or wasted blasts. Top underground drill jumbos shine here because they combine power with control, letting you work in narrow veins or steep inclines without missing a beat.

Key Roles in Daily Operations

These machines don’t sit idle. They lead the charge in development drilling, where you create new tunnels, or production drilling for ore extraction. In underground mining, every hole counts. A good jumbo ensures even spacing and depth, which means better fragmentation after blasting. That translates to easier loading and hauling later on.

Operators love them for the versatility. Some models handle single booms for tight spots, while others use double booms to cover more ground fast. It’s all about fitting the job. And in harsh conditions? They keep going, thanks to rugged builds that resist dust and vibration.

Features That Set Top Underground Drill Jumbos Apart

Not all drill jumbos are created equal. The best ones pack features that boost efficiency and cut down time lost to breakdowns. Let’s break it down.

Power and Drive Systems

Most top underground drill jumbos run on diesel for reliability in remote spots, but electric options are gaining ground for cleaner air underground. A strong engine – say, one that delivers steady torque – helps push through hard rock without stalling. Hydraulic systems power the booms, giving smooth movement and precise control. You want a setup that adjusts pressure on the fly, matching the rock type.

- Boom Design: Flexible arms that extend and rotate fully. This lets you drill at angles without repositioning the whole machine often.

- Drill Bits and Rods: High-quality steel that lasts. Look for systems that swap rods quickly to keep downtime low.

- Control Panels: User-friendly interfaces with joysticks and screens. Some even have remote options for safer operation from afar.

Tamaño y maniobrabilidad

In underground mining, space is tight. Top drill jumbos are compact yet powerful. Dimensions matter – a smaller turning radius means navigating narrow tunnels without hassle. Weights vary, but balanced designs prevent tipping on uneven ground.

Here’s a quick look at typical specs for these machines:

| Características | Common Range |

| Tramming Dimensions | Around 5-8m long, 1.5-2.5m wide |

| Potencia del motor | 50-100 kW |

| Profundidad del orificio | Up to 5m per rod |

| Peso | 20,000-30,000 kg |

| Carrier Type | Wheel-mounted for mobility |

These features make a difference. A jumbo with good hydraulics drills faster, saving fuel and wear on parts.

Safety isn’t an afterthought. Top models include anti-jamming tech that stops drills from getting stuck, reducing risks. Stable booms with accurate positioning cut the chance of rock falls. Plus, ergonomic cabs keep operators comfortable during long shifts, helping them stay alert.

How to Operate a Drill Jumbo Effectively Underground

Operating one of these beasts takes skill. It’s not just pushing buttons; it’s reading the rock and planning ahead. Start by positioning the machine securely – use outriggers for stability. Then, set up the booms to match your drill pattern.

In underground mining, visibility can be poor, so rely on lights and cameras. Drill slowly at first to gauge rock hardness, then ramp up. Watch for vibrations; they signal when to adjust. After drilling, retract carefully to avoid damaging the hole.

Common Challenges and Fixes

Tight turns? Practice maneuvering in open areas first. Dust buildup? Use water suppression systems to keep air clear. And always check hydraulics before starting – leaks can halt everything.

Operators who master this see big gains. Precise drilling means fewer blasts needed, speeding up the whole cycle. It’s rewarding work, building tunnels that last.

Jump in with hands-on practice. Learn the controls inside out. Simulate scenarios like drilling in low ceilings. Experienced teams often pair newbies with vets, sharing tricks that books miss.

Maintenance Strategies for Long-Lasting Performance

A top underground drill jumbo isn’t cheap, so keeping it in shape pays off. Regular checks prevent small issues from becoming big problems.

Daily and Weekly Routines

Start each shift with a walk-around: inspect tires, booms, and hoses for wear. Clean filters to fight dust. Weekly, grease joints and check fluid levels. It’s simple stuff, but it adds up.

- Boom Maintenance: Lubricate pivots daily. Replace worn bushings before they fail.

- Engine Care: Change oil on schedule. Monitor exhaust for signs of trouble.

- Electrical Systems: Test batteries and wiring, especially in damp tunnels.

Long-Term Overhauls

Every few months, dive deeper. Rebuild hydraulics if pressure drops. Align booms for accuracy. Use genuine parts to avoid mismatches. In underground mining, downtime hurts profits, so proactive fixes keep things moving.

Track usage hours. Rotate drills to even wear. Train staff on spot repairs. These steps stretch your budget and extend machine life.

Real-World Success Stories from Underground Sites

Seeing these jumbos in action tells the real story. In one South American mine, a reliable drill jumbo helped double tunnel advance rates. The team praised its stable booms for precise bolting, cutting rock fall incidents.

Over in Asia, a Philippine operation used one in narrow veins. It handled steep inclines without slipping, boosting ore output. Feedback from managers? The machine’s quick setup saved hours daily.

African sites report similar wins. A jumbo with strong hydraulics drilled through tough quartzite, reducing blast cycles. Operators noted easier handling, leading to fewer fatigue errors.

These cases show how top underground drill jumbos turn challenges into advantages, building trust in the gear and the teams behind it.

Meet Yantai Chi Hong Machinery Co., Ltd.: Your Go-To Supplier for Underground Drill Jumbos

When it comes to sourcing top underground drill jumbos, Yantai Chi Hong Machinery Co., Ltd. stands out. Based in Yantai, China, this company has spent over a decade building a solid name in underground mining equipment. They handle everything from design to after-sales support, with a big production base and a team heavy on tech experts. Certifications like ISO and CE back their quality. They focus on durable, efficient machines tailored for tough underground jobs, helping mines worldwide run smoother and safer.

Conclusión

Top underground drill jumbos are game-changers in underground mining, blending power, precision, and reliability to tackle the toughest tasks. From drilling deep holes to navigating tight spaces, they keep operations moving forward. With proper operation and maintenance, these machines deliver lasting value, cutting costs and boosting safety. If you’re ready to upgrade your setup, consider what a quality jumbo can do for your site.

Preguntas frecuentes

What is a top underground drill jumbo and why is it key in underground mining?

A top underground drill jumbo is a mobile rig used to drill holes in rock for blasting or support. In underground mining, it’s vital because it creates precise patterns quickly, speeding up extraction and improving safety by reducing unstable areas.

How do you choose the right top underground drill jumbo for your operation?

Look at your tunnel size and rock type. Pick one with flexible booms for tight spots and strong power for hard materials. Factor in ease of maintenance too – it keeps downtime low in underground mining.

What maintenance tips help extend the life of a top underground drill jumbo?

Compruebe hydraulics and booms daily for wear. Clean regularly to beat dust. Schedule deeper inspections every few months. This approach ensures reliable performance in demanding underground mining conditions.

Can top underground drill jumbos be customized for specific underground mining needs?

Yes, many suppliers offer tweaks like boom lengths or control systems. This fits unique site challenges, making the jumbo more effective in your underground mining setup.

How do top underground drill jumbos improve safety in underground mining?

They feature stable designs and anti-jamming tech to prevent accidents. Precise controls reduce errors, and remote options keep operators out of harm’s way during risky drills.