Protocolos clave de seguridad para camiones de transporte de minería subterránea

Importancia del mantenimiento y la inspección regulares

Camiones mineros subterráneos son cruciales. Mantienen las minas funcionando sin problemas. Los controles regulares garantizan la seguridad. Estos vehículos enfrentan condiciones difíciles. Yantai Chi Hong Machinery Co., Ltd hace hincapié en las inspecciones de rutina. Detectan desgaste. Los posibles fallos se detectan temprano. Los riesgos disminuyen bruscamente. Los sistemas hidráulicos necesitan atención. Los frenos y los neumáticos son clave. Las piezas de suspensión también son importantes. Los métodos avanzados ayudan. La instalación en frío de nitrógeno líquido protege los casquillos. Extende la vida útil del equipo. El mantenimiento ahorra costos.

Asegurar la formación adecuada para los operadores de camiones

Los camiones seguros necesitan conductores cualificados. La formación crea experiencia. Los operadores aprenden los controles del vehículo. Dominan los pasos de emergencia. Los túneles estrechos requieren habilidad. Yantai Chi Hong Machinery Co., Ltd proporciona capacitación. Su servicio posventa brilla. Los operadores ganan confianza. manejan escenarios difíciles. Los riesgos se minimizan. La formación cubre las normas de seguridad. Incluye la conciencia de peligros. Los conductores aprenden a reaccionar rápidamente.

Adherencia a las directrices de capacidad de carga

Sobrecargar camiones es arriesgado. Amenaza la seguridad. Se usan partes más rápidamente. Deben cumplirse los límites de carga. La estabilidad permanece intacta. Los accidentes se evitan. El camión de mina UK-6 es un modelo. Capacidad 6 toneladas. Yantai Chi Hong Machinery Co., Ltd lo diseñó para la eficiencia. Es seguro en túneles estrechos. La sobrecarga tensa los ejes. Los neumáticos se desgastan. Los frenos vacilan. Las directrices lo impiden.

Las minas aplican reglas estrictas. Los sensores de carga ayudan. Alertan a los conductores del exceso. Los supervisores verifican el cumplimiento. La sobrecarga ralentiza el trabajo y aumenta los costos. Las cargas seguras mantienen a los camiones estables. La navegación se vuelve mejor. Las minas funcionan más suavemente. Esta regla no es negociable. Protege a los trabajadores y el equipo. Yantai Chi Hong Machinery Co., Ltd construye para la seguridad. Sus camiones funcionan de manera fiable.

Desafíos en la operación de camiones de transporte minero subterráneo

Navegando por caminos estrechos e desiguales

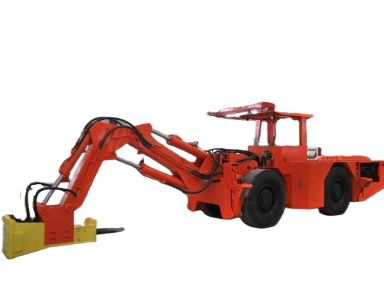

Los túneles están apretados. El terreno es duro. Esto desafía a los conductores de camiones. Los caminos estrechos limitan el movimiento. Terreno desigual sacude vehículos. El cargador WJ-1H está construido para esto. Su diseño es compacto. El radio de giro es pequeño. Se mueve fácilmente en lugares estrechos. Es posible una navegación segura. Los conductores evitan las paredes. Las colisiones son raras.

Las minas varían en tamaño. Algunos túneles tienen 2 metros de ancho. Las rocas salen. Los conductores necesitan enfoque. La formación ayuda aquí. La práctica crea habilidad. El diseño del equipo también importa. Los perfiles bajos reducen los enganches. Esto mantiene las operaciones seguras. Las minas dependen de la navegación inteligente. Es un desafío diario.

Gestión de la visibilidad limitada en entornos subterráneos

La visibilidad subterránea es baja. Ninguna luz solar llega a profundidad. Esto corre el riesgo de colisiones. Los camiones necesitan luces fuertes. Las cámaras y los sensores ayudan. Aumentan la conciencia. Los operadores ven obstáculos. Los riesgos disminuyen bruscamente. La tecnología es clave. Evita los accidentes. La seguridad mejora rápidamente.

La iluminación debe ser brillante. Los sistemas LED funcionan mejor. Duran más tiempo. Los sensores detectan el movimiento. Las alarmas advierten a los conductores. nubes de polvo vistas oscuras. La limpieza regular de las lentes ayuda. Los operadores permanecen alertas. La baja visibilidad es difícil. La tecnología inteligente lo hace manejable. Las minas dependen de estas ayudas.

Abordar los problemas de ventilación y calidad del aire

La ventilación es dura bajo tierra. El flujo de aire es limitado. Se acumulan gases dañinos. Los camiones diesel agregan humos. Esto perjudica la calidad del aire. Cargadores eléctricos como WJ-2 ayudan. reducir las emisiones. El aire se mantiene más limpio. Los trabajadores respiran más fácilmente. Los riesgos para la salud caen. Las minas necesitan buen aire.

Los sistemas de ventilación empujan el aire fresco. Los ventiladores limpian los humos. Los sensores rastrean los niveles de gas. Alertas advierten de peligro. El uso del diesel se está desvaneciendo. Los camiones eléctricos son más verdes. Se adaptan a espacios estrechos. La calidad del aire impulsa la seguridad. El aire malo ralentiza el trabajo. Las minas invierten en soluciones. Esto protege a todos.

Características de seguridad avanzadas para camiones de transporte de minería

El papel de los sistemas de prevención de colisiones

Los sistemas de colisión salvan vidas. Paran los accidentes. Los sensores detectan obstáculos. Las alarmas alertan a los conductores. Los camiones evitan las paredes. Otros vehículos son seguros. Las reacciones rápidas evitan los choques. Estos sistemas son inteligentes. Trabajan en túneles oscuros. La seguridad aumenta rápidamente.

Las minas están estrechas. Collisiones dañan el equipo. Retrasan el trabajo. Los sensores escanean constantemente. Cubren puntos ciegos. Los conductores ganan confianza. Los sistemas son fiables. Reducen los riesgos. Las minas las adoptan ampliamente. Esta tecnología es una necesidad.

Beneficios de las tecnologías de monitoreo en tiempo real

Monitoreo de la salud del camión. Comprueba los motores y los neumáticos. Los niveles de combustible aparecen. Yantai Chi Hong Machinery Co., Ltd utiliza diagnósticos inteligentes. Los problemas se detectan temprano. Las rupturas son raras. El mantenimiento está planificado. Los costos se mantienen bajos. El rendimiento se mantiene alto.

Flujos de datos en vivo. Los operadores ven alertas. La mecánica actúa rápidamente. Esto evita retrasos. Las minas funcionan 24/7. El tiempo de inactividad perjudica las ganancias. El monitoreo ahorra tiempo. Es un cambio de juego. Los camiones duran más. La seguridad también mejora.

Mejora de la estabilidad con sistemas de suspensión avanzados

La suspensión mantiene los camiones estables. El terreno desigual es duro. Sistemas avanzados conducen sin problemas. Los convertidores de par hidráulico ayudan. Las transmisiones de cambio de potencia agregan control. El cargador WJ-1H utiliza estos. Maneja terreno áspero. La estabilidad impide las puntas. La seguridad está garantizada.

Las minas son rocosas. Los camiones enfrentan sacudidas. La mala suspensión desgasta partes. Riesga rollovers. Los sistemas avanzados absorben golpes. Protegen a los conductores. Las operaciones se mantienen sin problemas. Esta tecnología es vital. Aumenta la confianza.

Mejores prácticas para la operación segura de camiones de transporte de minería subterránea

Comunicación y coordinación efectivas entre los operadores

La comunicación es clave. Garantiza la seguridad. Los operadores deben mantenerse en contacto. Las actividades necesitan sincronización. Esto reduce el riesgo de accidentes. Las radios bidireccionales funcionan bien. Los sistemas integrados son mejores. Ayudan a navegar por túneles. La coordinación es estrecha. Las señales de mano son estándar. Las conversaciones previas al turno alinean a los equipos. Los objetivos son claros. Se establecen normas de seguridad.

Las minas están ocupadas. Los camiones cruzan caminos. Los pasos equivocados causan choques. Las radios mantienen a los equipos conectados. Los briefings cubren los riesgos. Los operadores permanecen alertas. Esta práctica salva vidas. Mantiene las minas funcionando. La comunicación no es negociable.

Implementación de planes de respuesta a emergencias

Los planes de emergencia son vitales. manejan las crisis. Los pasos claros guían la evacuación. Se describen los primeros auxilios. La comunicación está establecida. Los planes se actualizan con frecuencia. Los controles de riesgo los moldean. El UK-6 Mine Truck ayuda aquí. Es ágil en espacios estrechos. Las salidas rápidas son posibles. Mejora la seguridad.

Los planes cubren incendios y colapsos. Las fugas de gas son riesgosas. Los trabajadores necesitan una acción rápida. Los planes se prueban anualmente. Salvan vidas. Las minas dependen de ellas. La preparación es clave. Yantai Chi Hong Machinery Co., Ltd apoya esto. Sus camiones se adaptan a las necesidades de emergencia.

Importancia de los ejercicios de seguridad rutinarios

Los ejercicios de seguridad preparan a los trabajadores. Imitan crisis reales. Se practican rutas de evacuación. Se ha aprendido el apagado del equipo. Se revisan los primeros auxilios. Los taladros encuentran puntos débiles. Se realizan mejoras. Los trabajadores ganan confianza. Las respuestas son más rápidas. Los taladros construyen una cultura de seguridad.

Normas regulatorias y cumplimiento en las operaciones de camiones mineros subterráneos

Resumen de las regulaciones de seguridad globales para vehículos mineros subterráneos

Las normas globales protegen a los trabajadores. Cubren el diseño de camiones. La formación del operador es obligatoria. El mantenimiento es estricto. El WJ-0.6 cargador cumple con los estándares. Su diseño es compacto. Navega por túneles estrechos. Las regulaciones reducen los riesgos. Garantizan un trabajo seguro. También mejora la eficiencia.

Cómo el cumplimiento mejora la seguridad y la eficiencia operacionales

El cumplimiento aumenta la seguridad. Agrega eficiencia. Los camiones tienen características inteligentes. Los sistemas de colisión son estándar. Se utiliza tecnología de monitoreo. El cargador WJ-2 reduce las emisiones. Cumple con las reglas verdes. Mejora la calidad del aire. Las auditorías capturan riesgos. Los problemas se solucionan temprano. Las operaciones se mantienen sin problemas.

Las regulaciones impulsan la innovación. Las minas adoptan nueva tecnología. Se mejora el equipo de seguridad. Los trabajadores están protegidos. La eficiencia aumenta. El cumplimiento ahorra costos. Es un win-win. Yantai Chi Hong Machinery Co., Ltd garantiza esto. Sus camiones cumplen con los estándares mundiales.

Preguntas frecuentes (preguntas frecuentes)

Cuáles son las características clave de camiones de transporte de minería subterránea?

Tienen diseños compactos. La maniobrabilidad es alta. Los sistemas de seguridad son avanzados. Se adaptan a espacios estrechos.

¿Cómo benefician los planes de respuesta a emergencias las operaciones mineras?

Guía las crisis. Las evacuaciones son rápidas. Los riesgos se minimizan.

¿Por qué es importante cumplir con las normas de seguridad globales?

Cumple con las normas de seguridad. Los accidentes caen. La eficiencia aumenta.

¿Qué papel desempeñan los ejercicios de seguridad rutinarios en la minería subterránea?

Preparan a los trabajadores. Las respuestas se practican. Las emergencias se manejan mejor.

Contáctenos para saber más sobre cómo Yantai Chi Hong Machinery Co., Ltd apoya prácticas mineras subterráneas seguras a través de soluciones de maquinaria innovadoras adaptadas a sus necesidades.