Глубоко под землей, добыча никогда не прекращается. Туннели крутятся, пыль удушает воздух, и каждая смена толкает передачу к краю. Если вы’ Если вы работаете или смотрите на новые платформы, вы знаете, что подземные грузовики подвергаются жестоким испытаниям каждый день. Тепло накапливается, вода просачивается, камни падают. Тем не менее эти машины тягут тонны без пропуска ритма. Продолжительность и производительность делают или разрушают их. В этом дайвинге мы’ Распакуем, как они сильны. От жестких конструкций до умных технологий, посмотрите, что держит их в экстремальных условиях.

Интересно, какой край они дают вашему сайту? Оставайтесь рядом. Мы’ ll покрыть реальные вызовы и твердые исправления.

Тяжелые пятна подземных шахтных грузовиков лицо

Подземная добыча бросает кривые шары. Узкие вены, крутые капли, влажные стены. Грузовики здесь don’ Просто ездите – они выживают.

Экстремальная тепла и плохой поток воздуха

Туннели захватывают тепло. Двигатели ревут, быстро поднимают температуру. Плохая вентиляция добавляет к нему, рискуя перегрев. Грузовики нуждаются в охлаждении, которое противодействует. Специальные системы захватывают воздух, охлаждающие жидкости. Это защищает части от искажения. В влажных местах влага съедает металл. Антиржавеющие пальта помощьБез них разрывы растут.

Холодные удары тоже. В замороженных шахтах жидкости сгустаются. Огреватели быстро нагревают их. Баланс – это ключ. Слишком жарко или холодно, снижение производительности.

Грубые туннели и тяжелые грузоперевозки

Пути’ t гладкий. Скалистые камни, грязные ямы, резкие повороты. Грузовики перевозят огромные грузы — руду, отходы. Рамки крутятся под весом. Шины схватывают свободную землю. Один скольз, и это’ Проблемы.

Узкие пространства ограничивают размер. Грузовики крутятся плотно, удобно вписываются. Но это означает больше напряжения на оси, суставы. Постоянная вибрация носит уплотнения. Сильный дизайн поглощает все.

Беги без остановки и дорогие остановки

Смены работают круглосуточно. Попадение грузовика означает потерянные тонны, большие деньги. Пылевые фильтры. Водные шорты проводы. Фиксы едят время. Итак, строит фокус на быстрых обменах, жестких деталях. Меньше простоя, больше выхода.

Очки на ежедневные удары:

- Пыль и зерно мелочные передачи.

- Водные наводнения со стен, испытания пломб.

- Крутые ступени, напряжающие тормоза.

Операторы чувствуют это. Безопасные, надежные грузовики снижают риски, повышают моральный дух.

Строит, что последует: секреты дизайна для долговечности

Подземные шахтные грузовики являются’ Т обычный. Каждый кусок укрепляется для борьбы.

Сильные рамы и шасси

Главное значение имеет база. Усиленная сталь принимает удары. Сварки держатся твердо, без трещин. Роботы сваряют точный, отжигающий металл. Это уменьшает слабые места.

Мешательство подходит для холодной установки - с использованием жидкого азота - блокирующих щеплений плотно. Защищает рамки от износа. Долгая жизнь под землей.

Подвеска и прочность шин

Ударит банку жестко. Усовершенствованная подвеска поглощает их. Предотвращает перевороты, охраняет двигатели. Шины? Толстые ступени, жесткие стены. Сопротивляются разрезам из острой руды. В грязи они копаются. Теплоустойчивая резина длится в парных туннелях.

Таблица сравнения типов шин:

| Особенность шины | Преимущества в экстремальных условиях |

| Толстые стены | Выносит проколы камней |

| Глубокие ходы | Ручки для мокрых, свободных поверхностей |

| Теплоустойчивый | Ручки туннельного тепла без взрывов |

Правые шины означают меньше плоскостей, стабильную тягу.

Запечатанные системы против пыли и воды

Грит скрывается повсюду. Уплотнители блокируют его от двигателей, гидравлики. Водонепроницаемый до уровня IP после проводки. Держит электрику сухой в наводнениях.

Вентиляторы фильтруют воздух, охлаждают без забора. Эта настройка борется с коррозией, продлевает пробеги.

Сила, которая работает: двигатели и системы в действии

Производительность сияет, когда сила встречает умность. Подземное, это’ с о крутящем моменте, эффективности.

Тяжелые двигатели для крутых подъемов

Двигатели упаковывают удар. Высокий крутящий момент тянет нагрузки вверх рамп. Дизельные типы обрабатывают пыль, но электрика получает землю. Чистый воздух, меньше шума.

Охлаждение имеет решающее значение. Радиаторы быстро промывают тепло. В узких местах подходят компактные конструкции.

Глотки топлива важны. Эффективные ожоги снижают затраты. Гибриды смешивают дизельное, электрическое — экономите на больших расстояниях.

Тормоза и трансмиссия для управления

Остановить тяжелые грузы? Мокрые дисковые тормоза уверены в сжатии. Автоматическая коробка передач смещается плавно, без тревог.

При снижении retarders замедляются без износа. Безопасность прежде всего - предотвращает бегцев.

Электрические варианты для более чистых ходов

Электричество процветает под землей. Без дыма, лучше для здоровья. Батареи сохраняют заряд на смены. Быстрые обмены продолжаются.

Гибриды лучше всего сочетаются. Энергия, когда это необходимо, зеленое, где это важно. Снижает выбросы, соответствует регламентам.

Технология, которая держит их сильными

Современные грузовики думают вперед. Датчики, аналитика рано обнаруживают проблемы.

Мониторинг проблем в реальном времени

Датчики наблюдают за температурой, давлением, износом. Покажутся оповещения Dash. Поймайте низкие жидкости, трещины, прежде чем они вырастут.

В темных туннелях это спасает жизни. Нет сюрпризов.

Прогнозивные инструменты для сокращения перерывов

Прошлые пробеги данных. Прогнозирует, когда детали отказываются. Исправления графика во время выхода. Меньше потерянных денег.

Пульки по технологическим преимуществам:

- Маршруты ИИ избегают опасностей.

- Автоматические системы снижают усталость оператора.

- Журналы отслеживают производительность, тонко настраивают операции.

Меньше крушений, более гладкие дни.

Техническое обслуживание перемещается для максимальной производительности

Обслуживание’ T после размышления. Это’ с ядром.

Регулярные проверки - четыре раза в гарантии - проблемы. Дважды тренировка держит экипаж острым.

Отчеты подробно о здоровье. Пользователи знают каждый болт.

Быстрый запас частей. Инженеры на вызов для установки, настроек.

Пользовательские конструкции соответствуют вашей шахте. Исправления скоростей удаленной помощи.

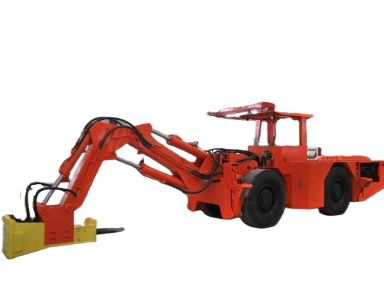

Yantai Chi Hong Machinery Co., Ltd.: Ваш поставщик подземных шахтных грузовиков

Yantai Chi Hong Machinery Co., Ltd. Устойчиво растет в подземной добыче на протяжении 12 лет. Они занимаются исследованиями, производством, продажами, обслуживанием. Топ в Китае’ с шахтного оборудования, достигая глобальных точек. База охватывает 96 000 квадратных метров. Более 300 производителей, 60 менеджеров, половина старших специалистов. Серты включают CE ЕС, ISO9001: 2015. Они изготовляют подземные свалы от 6 до 30 тонн, плюс погрузчики, ломачи, джумбо, инструменты, детали. В производстве используются лазеры, ЧПУ, роботы для резки, сварки, обработки. Сборка с азотом для жестких подъемов. Гарантия: бесплатные исправления 12 месяцев или 2000 часов двигателя. Срок выполнения 30-45 дней после оплаты. Удаленная онлайн помощь бесплатно; Инженеры для работы на месте, если это необходимо. На заказ да. Четыре проверки, два тренинга по гарантии, отчеты каждый раз.

Заключение

Подземные шахтные грузовики борются с экстремальными условиями, жесткими рамами, умной мощностью, технологическими преимуществами, грубыми дорогами, бесконечными сменами. Они тягут большесломать меньше. Для операций, требующих надежности, эти платформы обеспечивают. Сочетание долговечности и производительности для побед под землей. Готовы готовиться?

Часто задаваемые вопросы

Как подземные шахты выдерживают экстремальные условия, такие как тепло и пыль?

Подземные шахтные грузовики используют герметичные системы и сильное охлаждение для борьбы с теплом и пылью. Это повышает долговечность, поддерживает стабильную производительность в жестких туннелях.

Что делает долговечность ключом к подземным шахтным грузовикам в нестабильной местности?

Продолжительность происходит от усиленных рам и прочных шин на подземных шахтных грузовиках. Они справляются с тяжелыми нагрузками, вибрациями, обеспечивая длительные пробеги без сбоев.

Могут ли подземные шахтные грузовики поддерживать высокую производительность во время непрерывной работы?

- Да. - Да. Подземные шахтные грузовики оснащены прогнозирующей технологией и эффективными двигателями для максимальной производительности. Сокращает время простоя, хорошо справляется с экстремальными условиями.

Почему выбирать электрические варианты для подземных шахтных грузовиков в экстремальных условиях?

Электрические подземные шахты разрушают дымы, улучшают воздух в узких пространствах. Они поддерживают долговечность и производительность, подходят для жестких мест с меньшим обслуживанием.