Mining deep below ground throws up real tough spots. Narrow paths. Rough ground. Safety risks everywhere. That’s where underground mine trucks step in. These машины haul loads through tight spots and keep things moving. If you’re running a mine or planning one, knowing their advanced technical specifications matters a lot. It helps pick the right gear for better work and fewer headaches. This post digs into those details. We’ll look at build, power, safety, and what’s coming next. All to give you a clear picture on how these trucks boost your operation.

Core Design Elements of Underground Mine Trucks

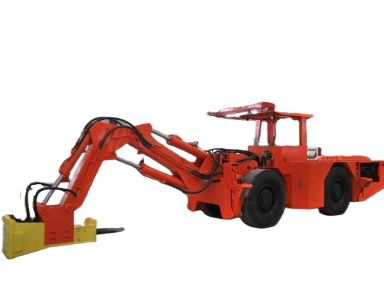

The heart of any underground mine truck lies in its build. It has to handle heavy stuff in cramped places. Think about the frame first. Strong steel makes it last. Welded tight, then treated to cut stress. This stops cracks under pressure.

Articulated Structure for Better Handling

Most trucks use a joint in the middle. This lets front and back parts twist free. Why? It helps turn sharp in narrow tunnels. The truck swings easy. Keeps tires in touch with the ground. Even on bumpy floors.

You see this in action during hauls. The design cuts wear on parts. Makes driving smoother. In tight mines, it means fewer stuck moments. Plus, it adds to stability. Less tip risk when loaded high.

A small turn circle changes everything. Some trucks turn in spots just a few meters wide. This fits small veins or crowded areas. Operators love it. They zip through without back and forth moves. Saves time. Cuts fuel use too.

Power and Drive Systems

Power keeps the грузовик going. Underground work needs strong pull. Engines push hard. Often diesel for torque. But new ones mix in electric bits for clean air down there.

Engine and Transmission Choices

Pick from different setups. High torque at low speeds helps climb slopes. Transmissions shift smooth. Torque converters add extra push. Drive axles grip firm.

These parts work together. They handle loads from several tons up. In steep drops or climbs, the system holds steady. No slips. Reliable runs mean more tons moved each shift.

Mines differ. So trucks adapt. Add fire stop systems. Or auto lube for less down time. Even emergency steers. These extras fit your site. Make the truck yours. Boost safety and cut stops.

Here’s a quick look at common specs in a table:

| Особенность | Typical Range | Benefit |

| Payload | 6 to 30 tons | Handles big hauls |

| Мощность двигателя | Up to 300 kW | Strong pull on inclines |

| Радиус поворота | 4 to 8 meters | Fits tight spaces |

| Размеры | 7-10m long, 2-3m wide | Navigates narrow tunnels |

This setup shows how specs tie to real use.

Safety Features Built In

Safety comes first underground. Trucks pack features to protect folks. From brakes to cabs.

Braking and Control Systems

Wet disc brakes stop quick. Even loaded. Foot valves add control. Some have auto slow on slopes. Keeps speed safe.

Cabs seal tight. Air inside stays clean. AC keeps cool. Ergonomic seats cut fatigue. Visibility high with lights and cams.

Fire suppress systems kick in fast. Hoses and tanks ready. Emergency steers if power fails. These save lives in bad spots.

- Rollover guards.

- Gas monitors.

- Escape paths.

All add layers of guard.

Innovations Shaping the Future

Tech pushes trucks forward. Autonomous runs cut risks. No driver in harm’s way.

Autonomous and Electric Advances

Self-drive trucks use sensors. Map paths. Avoid hits. Run non-stop. Boost output.

Electric versions cut fumes. Batteries last long. Charge quick. Less noise too. Good for health down deep.

These changes meet green rules. Cut costs over time. Mines switch for better air and less fuel bills.

Sensors track everything. Real-time info on loads, health, paths. Spot issues early. Fix before breaks.

This tech ties to mine plans. Routes get smarter. Less wait. More flow.

Real-World Performance from Case Studies

Trucks prove worth in actual mines. In Peru, tight quality checks made them reliable. Handled tough ground without fails.

Philippines sites saw long life from good parts. Machining kept accuracy high. Less wear.

South Africa ops praised strong frames. Welds and treatments fought rust and stress. Assembly tests ensured ready for work.

These stories show specs in action. Efficiency up. Down time down. Happy teams.

Benefits for Your Mining Operation

Pick right trucks, and your site thrives. More tons per day. Safer shifts. Lower costs.

Think long term. Good specs mean less fixes. Steady runs build trust. Your brand grows as reliable.

It lifts the whole team. Operators feel safe. Managers see numbers improve. Everyone wins.

Building a Stronger Setup

Mix these trucks with other gear. Loaders, drills. All work smooth. Your mine turns efficient. Ready for growth.

О компании Yantai Chi Hong Machinery Co., Ltd.

As a top supplier of underground mine trucks, Yantai Chi Hong Machinery Co., Ltd. brings 12 years of steady growth in the field. With a big production base over 96,000 square meters and more than 300 skilled workers, the company focuses on quality. They hold EU CE and ISO9001:2015 certifications. Offering trucks with capacities from 6 to 30 tons, they provide full systems for research, making, sales, and service. Their after-sales includes free fixes for a year or 2000 engine hours, plus training and checks. This setup helps mines worldwide run smooth and safe.

Заключение

Advanced technical specifications make underground mine trucks key players in mining. From strong builds to smart tech, they handle tough jobs with ease. Pick wisely, and you see real gains in safety and output. As tech grows, these machines will keep pushing limits. Stay ahead by knowing these details. Your operation depends on it.

Часто задаваемые вопросы

What are the main advanced technical specifications to look for in underground mine trucks?

Focus on payload from 6 to 30 tons, tight turning radii, and strong engines. These help in narrow spots and heavy hauls. Add safety like wet brakes and fire systems for full protection.

How do advanced technical specifications improve safety in underground mine trucks?

They include sealed cabs for clean air, auto brakes, and emergency steers. These cut risks in dark, tight areas. Real-time sensors spot dangers early too.

Can underground mine trucks with advanced technical specifications handle custom needs?

Yes. Options like auto lube or electric mixes fit your site. This makes them work better in specific mines, cutting down time and boosting loads.

What’s next for advanced technical specifications in underground mine trucks?

Look for more autonomous runs and electric power. These cut fumes and run longer. Data tools will track performance, making ops smarter and greener.