Ever stared at a rock face and wondered how to break through without wasting time or money? Choosing the right rock drill tool can make or break your work. It’s not just about grabbing any bit or rod off the shelf. You need something that fits your site, handles the rock type, and keeps your team safe. In this guide, we’ll walk through the steps to pick the best one for your job. Whether you’re digging tunnels or blasting quarries, getting this right boosts your output and cuts down on headaches.

Why the Right Tool Matters in Rock Drilling

Think about it. A mismatched tool leads to slow progress, broken parts, and extra costs. But when you choose wisely, everything flows better. Your drills last longer, your holes come out cleaner, and your whole operation runs smoother.

The Impact on Project Efficiency

A good tool speeds up drilling. It penetrates hard surfaces with less effort. This means fewer stops for repairs and more ground covered each day. Imagine finishing a shift with targets met instead of fixing jams.

Safety plays a big part too. Tools that fit well reduce vibrations that tire out operators. They also lower the chance of accidents from slips or breaks.

Long-Term Benefits for Your Operation

Over time, the right choice saves cash. Less wear on your machines. Fewer replacements. And a reputation for reliable work that brings in more jobs. It’s about building trust in your brand as someone who gets things done right.

Assessing Your Project Requirements

Start here. Know what you’re up against. Every site is different, so tailor your pick to the details.

Evaluate the Rock Type and Hardness

Rocks vary. Granite bites back harder than sandstone. Test samples if you can. Use a simple scratch test or lab analysis to gauge hardness. Softer rocks might need finer tips to avoid crumbling. Harder ones call for tougher materials that won’t dull fast.

Consider moisture too. Wet conditions change how tools perform. They might need coatings to resist rust.

Consider the Scale and Depth of Drilling

How deep do you go? Shallow holes for anchors differ from deep blasts in mines. Longer rods handle depth but add weight. Think about hole diameter as well. Wider holes require stronger shanks to avoid bending.

For big projects, factor in volume. High-volume drilling needs tools that stay sharp through many cycles.

Environmental Factors on Site

Weather hits hard. Cold snaps make metal brittle. Heat warps parts. Pick tools rated for your climate.

Dust and debris? Tools with good flushing channels clear chips better, keeping drills cool and clean.

Exploring Types of Rock Drill Tools

Many options out there. Each suits certain jobs. Let’s break them down.

Button Bits vs. Cross Bits

Button bits shine in hard rock. Their rounded inserts crush efficiently. They last longer in abrasive conditions.

Cross bits work well in softer or fractured rock. The X-shape cuts clean and evacuates debris fast. But they wear quicker on tough surfaces.

| Tool Type | Лучшее для | Pros | Cons |

| Button Bits | Hard, abrasive rock | Durable, high penetration | Higher initial cost |

| Cross Bits | Soft, fractured rock | Good chip removal, affordable | Faster wear in hard conditions |

Rods and Shanks: Length and Material Choices

Rods connect your drill to the bit. Steel ones are common for strength. But carbide-tipped versions resist bending better.

Length matters. Short for precision work. Long for reach in tight spots. Always match shank to your machine for a secure fit.

- Steel rods: Tough and flexible.

- Carbide inserts: Add edge life.

- Threaded ends: Ensure tight connections without slips.

Accessories Like Couplings and Adapters

Don’t overlook these. Couplings link rods smoothly. Adapters fit odd setups.

Pick ones with precise threads to avoid leaks or breaks. Quality here prevents downtime.

Key Features to Look For in Quality Tools

Not all tools are equal. Spot the good ones by checking these traits.

Material Composition and Heat Treatment

High-carbon steel holds up. Heat-treated tools resist fractures. Look for even tempering that balances hardness and toughness.

Coatings help too. They fight corrosion in damp sites.

Design Elements for Performance

Flute design clears waste. Deeper flutes handle more debris.

Tip geometry affects cut. Conical for speed, ballistic for tough rock.

Compatibility with Your Drilling Equipment

Match to your rig’s power. Too weak, and it bogs down. Too strong, and it shatters tools.

Check thread types. Common ones like R32 or T38 fit most, but confirm.

Balancing Cost and Value

Price tags tempt, but think long haul.

Initial Investment vs. Lifecycle Costs

Cheap tools break often. Spend more upfront for ones that last. Calculate total ownership: purchase plus repairs.

A sturdy tool might cost double but run five times longer. That’s real savings.

Maintenance and Replacement Considerations

Easy-to-clean tools save time. Modular designs let you swap parts without full replacements.

Plan for spares. Keep extras on hand to avoid halts.

Supplier Support and Warranties

Good suppliers back their goods. Look for warranties covering defects. Quick parts delivery keeps you moving.

Tips for Testing and Selecting Suppliers

Try before you buy. Field tests show true performance.

Conducting On-Site Trials

Run tools in your conditions. Measure speed, wear, and ease.

Compare a few to see differences.

Оценка репутации поставщика

Check reviews. Talk to past buyers. Reliable ones have solid track records.

- Years in business: Shows stability.

- Certifications: Like ISO for quality.

- Customer stories: Real proof of results.

Custom Options for Unique Projects

Some jobs need tweaks. Good suppliers offer custom lengths or materials.

This fits your needs exactly, lifting your work above standard.

Common Mistakes to Avoid

Learn from others’ slips.

Overlooking Tool Compatibility

Mismatch leads to failures. Always double-check specs.

Ignoring Operator Feedback

Your team knows best. Listen to their input on feel and performance.

Skimping on Quality for Short-Term Savings

It backfires. Poor tools slow you down and hike costs later.

Building Your Brand Through Smart Choices

Picking well shows expertise. Clients notice smooth operations. It builds your name as a pro who delivers.

Share your successes. Case studies highlight how right tools boosted your projects. This draws more business.

In a competitive field, these decisions set you apart.

Introducing Yantai Chi Hong Machinery Co., Ltd.

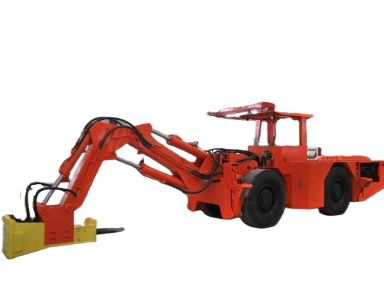

As a trusted supplier in the underground mining world, Yantai Chi Hong Machinery Co., Ltd. stands out for its focus on rock drill tools. With over a decade in the game, this company runs a large production base in China, churning out gear that meets high standards like EU CE and ISO certifications. They cover everything from loaders to trucks and drilling bits, all built with a keen eye on quality. Their team includes skilled workers and tech experts who push for better designs. Plus, they offer solid after-sales help, like maintenance plans and quick fixes, to keep your site running. If you’re after dependable tools, they’re worth a look.

Заключение

Wrapping up, choosing the right rock drill tool boils down to knowing your site, picking features that match, and teaming with solid suppliers. Get this right, and your projects hum along with fewer snags and better results. It’s about making smart picks that pay off in the long run.

Часто задаваемые вопросы

What factors should I consider to choose the right rock drill tool for my project?

Look at rock hardness, hole depth, and site conditions first. Then match materials and designs to your rig for best fit and safety.

How does the rock type affect picking the right rock drill tool for your project?

Hard rocks need durable bits like buttons for longevity. Softer ones do well with cross bits for clean cuts and easy debris removal.

Can custom options help in choosing the right rock drill tool for your project?

Yes, tweaks like special lengths or coatings tailor tools to unique sites, improving performance and cutting waste.

Why is supplier support key when selecting the right rock drill tool for your project?

Good support means quick parts, warranties, and advice, keeping downtime low and your operation steady.