In the world of underground mining, every second counts. You face tight spaces, tough rocks, and the constant push to get more done with less risk. That’s where an underground rock breaker comes in. This piece of equipment breaks down large rocks right at the source. It helps clear paths faster and keeps things moving. Miners know the frustration of stuck boulders slowing everything. An underground rock breaker tackles that head-on. It boosts underground mining efficiency by cutting wait times and making operations smoother. Let’s dive into how it works and why it matters for your team.

Think about a typical day underground. Blasting leaves big chunks that jam up loaders or conveyors. Without the right tool, crews spend hours chipping away manually. That’s dangerous and slow. But with a rock breaker, you attach it to a machine or use it standalone to smash those obstacles. The result? Quicker cycles, safer work, and better output. We’ll cover the basics, features, and real benefits here. Stick around to see how this tool changes the game.

了解地下破碎机

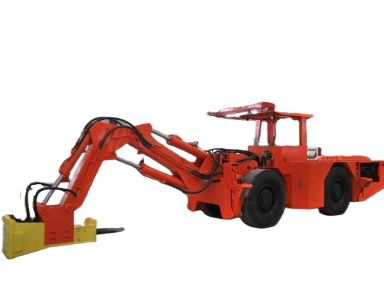

An underground rock breaker is built for harsh conditions below ground. It uses hydraulic power to deliver strong blows through a chisel or hammer. The machine mounts on a carrier like a loader or excavator arm. This setup lets it reach into tight spots. Power comes from the carrier’s system, so no extra engines clutter the space.

Operators control it from a safe distance. The breaker vibrates less than older models, which cuts fatigue. It handles various rock types, from soft limestone to hard granite. Size matters too. Compact designs fit narrow tunnels, often under 3 meters wide. Weight keeps it stable without tipping the carrier. In short, it’s a tough, simple tool that gets the job done where others can’t.

Why It’s Essential in Modern Mining

Gone are the days of relying solely on explosives or hand tools. Today’s mines demand speed and precision. An underground rock breaker fills that gap. It reduces the need for secondary blasting, which saves on explosives and time. Plus, it minimizes ore dilution by breaking only what’s needed. For mine managers, this means lower costs per ton extracted. Workers appreciate the reduced exposure to hazards like falling rocks.

Consider the workflow. After drilling and blasting, fragments can block haulage ways. A breaker clears them fast, letting trucks or scoops load without delay. This keeps the whole chain efficient. Studies in the industry show operations with breakers see up to 20% faster cycle times. It’s not just about breaking rocks—it’s about keeping momentum.

Key Features That Drive Performance

地下岩石破碎机 come with traits tailored for mining challenges. These aren’t fancy add-ons; they’re practical elements that make a difference daily.

- Hydraulic Power System: Draws energy from the host machine. Delivers consistent force without overheating. Quick response times mean faster strikes.

- Durable Chisel Tips: Made from hardened steel. They resist wear in abrasive environments. Easy to swap when dull.

- Vibration Dampening: Built-in absorbers reduce shakes. This protects the operator and extends machine life.

- Compact Build: Low profile for confined areas. Yet strong enough for heavy-duty tasks.

Take the power system, for example. It adjusts force based on rock hardness. Soft material gets light taps; tough stuff gets full power. This smart use saves energy and wear.

Safety Enhancements Built In

Safety isn’t an afterthought. These breakers include guards against flying debris. Remote controls let operators stay back. Automatic shut-offs prevent overloads. In dark tunnels, visibility aids like lights integrate seamlessly.

One key aspect: reduced dust and noise. Modern designs muffle sounds below harmful levels. Water suppression options cut airborne particles. Workers breathe easier, literally. This leads to fewer health issues over time.

Maintenance-Friendly Aspects

No one wants downtime for repairs. Underground rock breakers use modular parts. Swap a hose or seal in minutes. Grease points are accessible. Regular checks keep them running smooth.

Many have diagnostic ports. Plug in a tool to spot issues early. This proactive approach avoids big breakdowns. In the end, it means more uptime for your operation.

How Underground Rock Breakers Boost Efficiency

This is the heart of it. An underground rock breaker boosts underground mining efficiency in clear, measurable ways. Let’s break it down.

Reducing Downtime in Operations

Downtime kills profits. When rocks block the way, everything stops. A breaker smashes them quickly. No waiting for crews with jackhammers. In one shift, you might save hours.

Picture a haul truck stuck behind a boulder. Instead of calling in explosives, the breaker operator clears it in moments. Cycles speed up. More loads per day add up fast.

Enhancing Productivity Through Faster Clearing

Productivity jumps when clearing is swift. Breakers handle oversized material at the face. This lets loaders grab clean ore. Less sorting later on.

In narrow vein mines, space is tight. A breaker fits where big machines can’t. It preps the area for drilling or loading. Teams move from one task to the next without pauses. Output rises without extra labor.

Here’s a quick look at potential gains:

| 方面 | Without Breaker | With Breaker |

|---|---|---|

| Clearing Time per Boulder | 30-60 minutes | 5-10 minutes |

| Daily Loads Handled | 50 | 70 |

| Ore Dilution Rate | 15% | 8% |

Numbers like these come from field reports. They show real impact on the bottom line.

Improving Safety and Worker Morale

Safe workers are efficient workers. Manual breaking risks injury from slips or strains. A machine takes that burden. Operators control from cabs with protection.

Fewer accidents mean less lost time. Morale improves when teams feel secure. Happy crews work harder and smarter. It’s a cycle that builds efficiency over time.

Cost Savings Over the Long Haul

Upfront, a breaker adds to equipment costs. But payback comes quick. Less explosive use cuts expenses. Fewer repairs from jammed machines save money.

Fuel efficiency improves too. Carriers run less idle time. Over a year, savings can reach thousands per unit. For fleet managers, it’s a smart investment.

Real-World Applications in Underground Mining

See it in action. In metal mines, breakers clear post-blast debris. Gold operations use them to break vein walls precisely. Coal seams benefit from reduced overbreak.

One example: a tunnel project faced hard quartz blocks. Adding a breaker cut clearing time by half. Production hit targets ahead of schedule.

Another case: a deep mine with narrow drifts. The breaker mounted on a small loader. It handled daily obstructions without halting shifts. Efficiency rose 25%.

These stories show versatility. From small-scale to large ops, the tool adapts. It fits various carriers, making it flexible for different sites.

Challenges and Solutions in Implementation

Not every mine is the same. Wet conditions can slip tracks. Solution: anti-skid tires. Power supply issues? Hybrid options help.

Training matters. Short sessions teach operators the ropes. Once familiar, they maximize the tool’s potential.

关于烟台驰鸿机械有限公司.

烟台驰鸿机械设备有限公司 stands as a reliable supplier of underground rock breakers and other mining gear. With over a decade in the field, the company has built a solid system for research, making, sales, and support. Based in Yantai City, China, it covers a large production area and employs hundreds of skilled workers. Half its technical staff hold senior roles. Certifications like EU CE and ISO 9001 back its quality focus. The firm offers a range of underground equipment, including loaders, trucks, and breakers. It emphasizes innovation and customer needs, serving markets worldwide. After-sales includes free upkeep for a year or set hours, plus spare parts and tech advice. This commitment helps mines run better and safer.

结论

Wrapping up, an underground rock breaker stands out as a key player in boosting underground mining efficiency. It cuts downtime, ramps up productivity, and keeps costs in check—all while prioritizing safety. For mining teams pushing limits below ground, this equipment delivers real results. It turns challenges into smooth operations. If you’re looking to step up your game, consider how it fits your setup. The gains speak for themselves.

常见问题解答

What makes an underground rock breaker essential for boosting underground mining efficiency?

An underground rock breaker handles large rocks quickly after blasts. This speeds up clearing, reduces waits, and lets teams load and haul faster. It fits tight spaces, cutting manual work and risks.

How does using an underground rock breaker improve safety in mines?

It keeps workers away from dangerous manual breaking. Remote controls and guards protect against debris. Less vibration and noise mean healthier conditions, boosting underground mining efficiency through fewer incidents.

Can an underground rock breaker lower costs while boosting underground mining efficiency?

Yes. It saves on explosives by reducing secondary blasts. Faster cycles mean more output per shift. Maintenance is straightforward, extending equipment life and trimming repair bills.

What features should I look for in an underground rock breaker to maximize efficiency?

Seek hydraulic systems for strong, adjustable power. Durable tips and vibration control help longevity. Compact size suits narrow tunnels, ensuring it boosts underground mining efficiency without hassle.

How do I integrate an underground rock breaker into my existing operations?

Start with carrier compatibility checks. Train operators on controls. Regular checks keep it running. Suppliers offer guidance to ensure it boosts underground mining efficiency from day one.